With Boris Johnson’s promise to “build, build, build”, and the Covid-19 pandemic forcing new ways of working to ensure workers are kept socially distanced, offsite construction methods are set to continue to grow in the industry.

From housing, hotels to hospitals, offsite construction is already providing several benefits. Increasing speed of build, being more cost effective, having a controlled environment to build in, and minimising the impact on the site and surrounding neighbours, offsite construction is going to play an important part in meeting the housing shortage, delivering the 40 hospital projects the government has promised to complete by 2030, and also coping with the lack of skills in the industry.

On The Level’s bespoke shower floors provide the perfect solution for offsite manufacturing partners. Our made to measure shower floors are delivered direct to our partners factories and are ready to drop into volumetric modular buildings, steel frame bathroom pods and factory built houses.

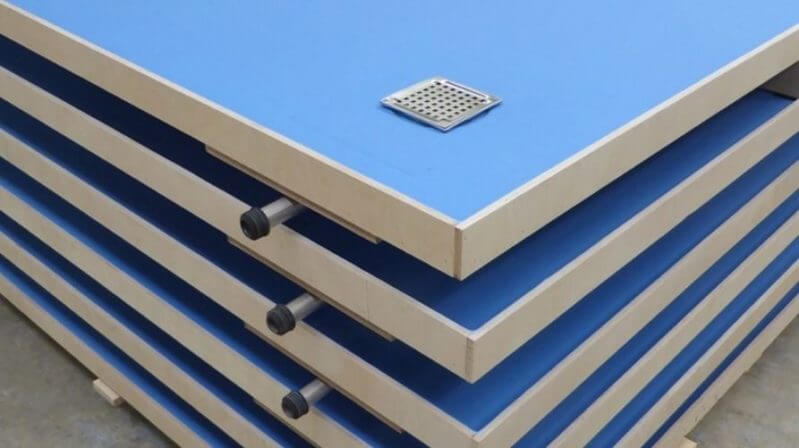

Our floors are manufactured from high quality birch ply material and have falls created in shower areas, providing a gradient for floor finishes to follow and in turn, a path which water can flow quickly into the waste gully.

In addition, our Ultimate floors incorporate perimeter upstands making it easier to erect walls, using the floor as a template once positioned. The floors are supplied with gullies, waste supports, and come completely pre-tanked, saving time for our partners.

As our specialism lies in bespoke formers and drainage systems, we can create wet room floors to any shape or size and have the gully positioned to suit the requirements of our offsite manufacturing partners.

We are excited to play our part in the future of UK construction. Contact us to discuss your next modular project.