Steve Rockall of Ellmark explains : “We first worked with OTL approximately 10 or 11 years ago when we converted a shoe factory called The Top Boot Factory, in Northampton, into a total of 12 apartments, for which OTL supplied all the shower formers. The quality of the work and team was such that we were only too happy to come back to OTL for this latest project, for a large new build house where we needed a bespoke solution for the wet rooms”.

Mark Crabtree of On The Level continues the story : “Ellmark called OTL to ask if we could help with linear channels which really needed to be made bespoke, as the contractor had already drilled through the floor slab to accommodate linear drainage channels”.

There were 4 wet rooms in total, all different sizes ranging from 1430mm x 900mm to 1800mm x 1000mm. OTL manufactured bespoke 2-way fall linear formers, with the waste positions aligned specifically to fit in with existing hole cutouts in the concrete slab that had been already cored onsite. It was not possible for new holes to be drilled as for this could have impacted the strength load bearing of the concrete slabs.

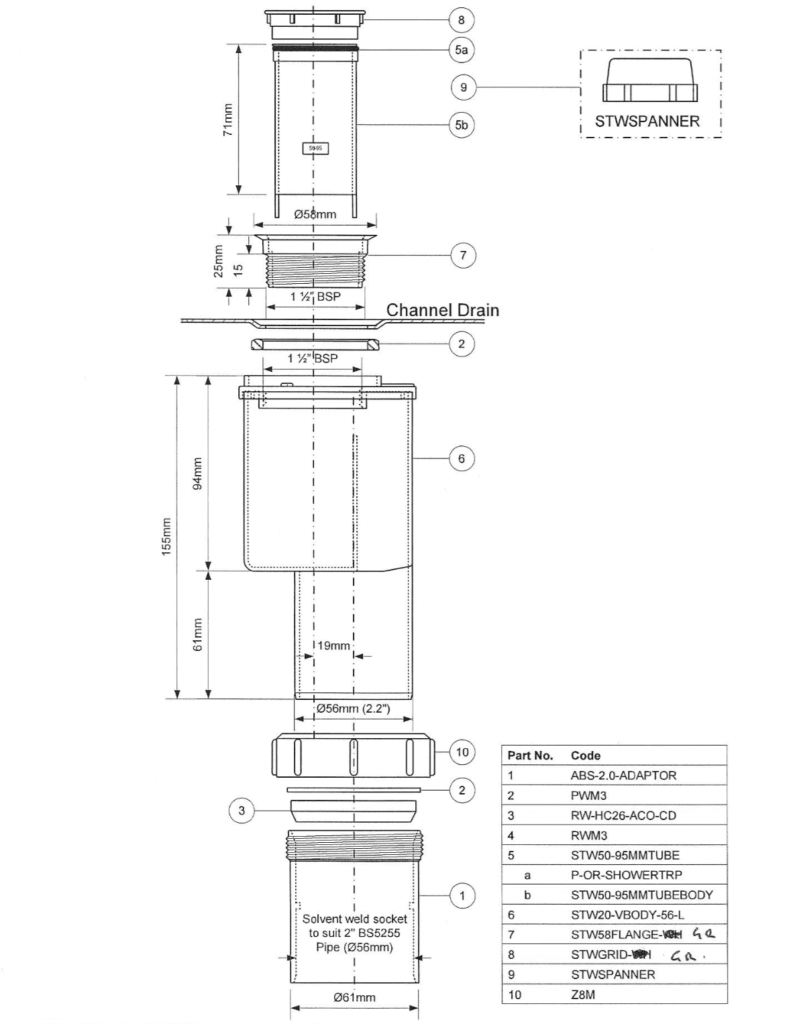

Vertical type gullies were used on this project so that the the waste could be connected in the void below the structural concrete floor slab. This made installation simple as the waste pipe could be connected from below working from the ground floor.

OTL SuperSlim Linear channels were also the client’s choice, which give a streamlined, sleek appearance, with water draining through a 4mm shadow gap into the linear channel sump.

Mark adds: “It was a real pleasure to work with Ellmark, a truly fine building contractor who are perfectionists like On The Level. We look forward to working together again soon.”

Steve Rockall of Ellmark summed up: “The On The Level team and the products are ideally suited for this type of project, taking an individual client’s bespoke requirements and producing a quality product – with a professional back up and support network to achieve the desired result for the client”.